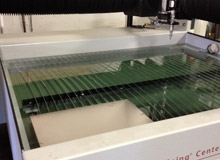

In line with our reputation as a hybrid manufacturer, Agwey Metals is pleased to offer precision Waterjet cutting services in addition to our other manufacturing and fabrication capabilities. This green technology will not thermally distort materials, it reduces or in many cases eliminates the need for secondary operations, and the end product boasts smooth finished edges. We provide intricate etching and scribing of an array of materials including steel, aluminum, beryllium copper, brass, titanium, and a host of other standard and exotic metals. This service is available to customers needing a full production run, or a one-off project.

Our state-of-the-art Waterjet cutting equipment offers 3-axis cutting, with nozzle pressure of 60,000 psi, with a maximum cutting width and length is 48″. We hold cutting tolerances as close as ±.005″, handling materials up to 6″ thick. Employing a range of pressure we can produce edge quality of 1 through 5, with a kerf of .024″. Material raw forms we work from include coil, sheet, bar stock, or plate. To learn more about our advanced Waterjet cutting process or the other value added services we offer please see the chart below or contact us directly.

Precision Waterjet Cutting Capabilities

| Characteristics | Minimum Part Stress No Thermal Distortion or Hardening Reduced Material Cost Through Nesting | Reduction or Elimination of Secondary Operations Smooth Finished Edges |

| Processes | Scribing Etching | |

| Cutting Axis | 3-Axis | |

| Thickness | Up to 6 in | |

| Cutting Width | Up to 48 in | |

| Cutting Length | Up to 48 in | |

| Edge Quality | 1 to 5 | |

| Nozzle Pressure | 60,000 psi | |

| Kerf | .024 in | |

| Tolerance (+/-) | .005 in | |

| Materials | Steel Stainless Steel Aluminum Brass Beryllium Copper Havar | Hastelloy Nispan C Invar Titanium Inconel Monel |

| Raw Material Forms | Coil Sheet | Bar Stock Plate |

| Intended Application | Components | Brackets |

| Additional Services Provided | Drilling Tapping Threading Reaming Sub-Assembly | Spot Welding Kitting Sandblasting/Glass Bead Timesaving |

| Production Volume | Short to Medium Run | |

| Delivery Options | Just In Time (JIT) | Kanban |

Additional Information

| Industry Focus | Aerospace Medical | Waterflow and Filtration Industrial |

| File Formats | SolidWorks |